+86 0755-29784870

+86 0755-29784969

5th Floor,No.B Building ,Huafeng Industrial Zone, Gushu Hangcheng Street, Xixiang Town, Bao'an District, Shenzhen City, China

Application of SINOVO Frequency Converter in Screw Extruder of

Melt Blown Fabric Production Equipment

Preface:Under the COVID-19 situation, the face mask demands valume is increasing for the people used, as the main raw material of the Meltblown on the mask, it also has great demand in the production of masks of the Enterprises.

This passage main introduced the application of SINOVO frequency inverter in the Screw Extruder of Melt Blown Fabric Production Equipment

Keywords: Meltblown SINOVO Frequency inverter face masks COVID-19

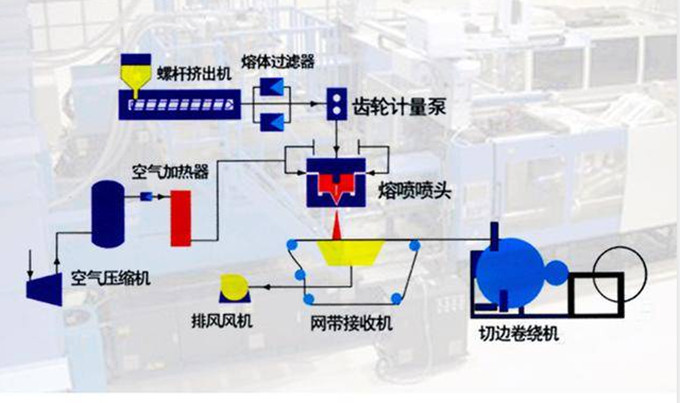

I. The Brief Introduction of Melt Blown Fabric Production Process

The production process of meltblown cloth:raw materials---->Melt extrusion---->filter---->Measure(Metering pump for meltblown cloth)---->Air heating and compression---->Meltblown---->Becoming net---->Winding.

Melt Extrusion is the most important part of the manufacturing process of meltblown fabrics.

II. Introduction of screw extruder

Screw extruder is an automatic feeding equipment. It is mainly composed of screw, barrel, head, feeding mechanism and transmission device. The plastic is plasticized into a uniform melt by an extruder, and the head is continuously extruded through a screw with constant temperature, quantitative and top pressure. The screw speed directly determines the production efficiency and production quality, and has a high requirement for the stability of the speed. At the same time, the resistance is very large when the extruder is started, which requires the motor to output enough torque at low frequencies.

III. The advantages of SINOVO frequency converter used in the screw extruder.

1) Energy-saving:

According to the VFD running V/F curve, the vfd is a constant torque output,compared to adjust

speed systems, it can be save the electricity power more than 30%, and the significant effect energy-saving under the low frequency running.

2) Improve product quality: variable frequency speed regulation performance is quite stable;

3) Reduce the impact on the power grid during start-up:

the start-up current can be controlled within the rated current without forming an impact on the power grid, reduce the impact on the machine during dynamic start-up, and smooth start-up can prolong the service life of the machine;

4) Meet the requirements of stepless speed regulation: simple speed regulation, convenient operation and powerful protection function.

5) Low harmonic output, effectively extend the life of the motor.

6) Super strong automatic torque boost function, automatically provide super large starting torque.

IV. The Application pictures.

V. The ending.

During the commissioning process, the SINOVO frequency converter running stably and with the large low-frequency torque which fully meet the customers demand. SINOVO Electric, as an R & D and production enterprise of automation products, provided frequency converters for some meltblown fabric production equipment companies under the COVID-19. We play an active role contributed own strength to fight the disease.