+86 0755-29784870

+86 0755-29784969

5th Floor,No.B Building ,Huafeng Industrial Zone, Gushu Hangcheng Street, Xixiang Town, Bao'an District, Shenzhen City, China

Abstract: According to the development trend of grinding equipment industry, PLC should become more and more popular in the industry. The SINOVO PLC use in the grinding equipment application has passed multi-party verification to meet customer development requirements, and achieved good results.

Lapping Machine Profile

Lapping machine via vibrating the spring to drive the vibrating plate in the grinding mixture (grinding materials, grinding parts, grinding aids and other mixtures) to produce three directions of movement, that is up and down vibration, from the inside out flip, spiral clockwise rotation to grind a grinding equipment. Lapping machine control system takes PLC as the control core and text display as the HMI control way. HMI can dialogue on the equipment maintenance, operation, failure and other information; intuitive user interface, program control, simple operation. Comprehensive safety considerations, non-normal operation of the wrong operation is invalid. It can achieve real-time monitoring, fault, error alarm and easy maintenance.

Control Principle

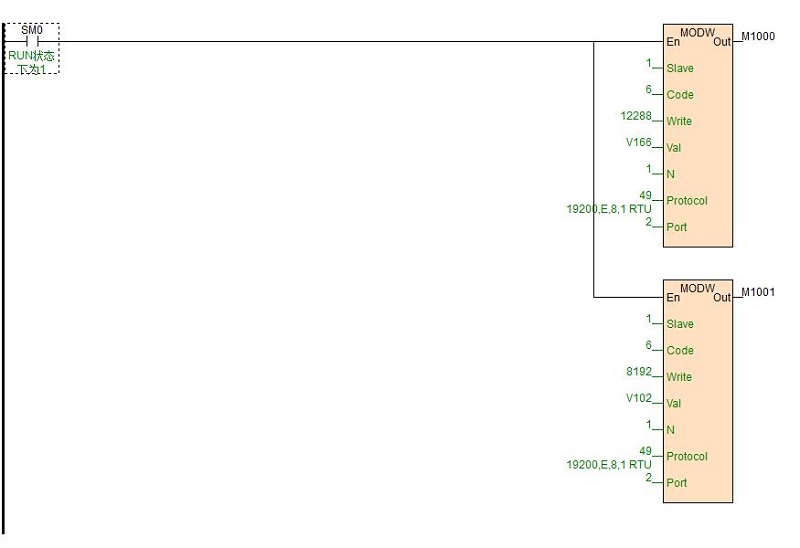

Lapping machine control system consists of SINOVO PLC system, touch screen, solenoid valve (drive cylinder), inverter, inverter motor and other low-voltage electrical components and other components.

1. System Configuration:

System configuration as follows:

|

No. |

Name |

Model |

Unit |

Quantity |

|

1 |

HMI |

TK6070IP |

Piece |

1 |

|

2 |

SINOVO PLC |

C16S2R |

Piece |

1 |

|

3 |

SINOVO AC Drive |

SD100-4T-5.5G/7.5P |

Piece |

1 |

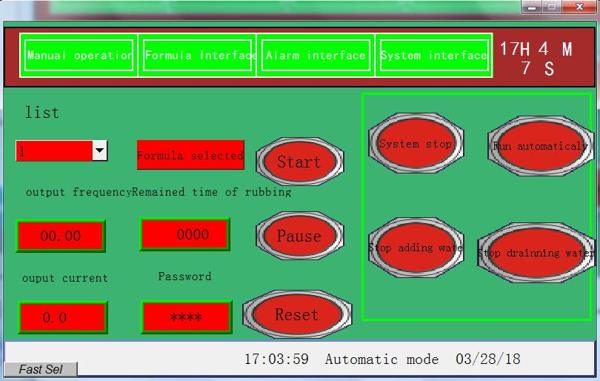

User can modify the HMI parameters to set grinding time, add water time and drainage time, which not only can view the remaining time grinding, but also can starting and stopping equipment. When the equipment is abnormal, the alarm information is timely sent to the HMI to remind the operator to deal with the emergency. Project menu to use the recipe to do, you can choose the distribution parameters in 30 to meet the needs of customers in the grinding of different materials. Touch screen as shown below: